2.2.1 Definitions

A thermal block is a space or collection of spaces within a building having sufficiently similar space conditioning requirements so that those conditions could be maintained with a single thermal control device. A thermal block is a modeling construct that combines similar thermal zones. Thermal zones need not be contiguous to be combined into a thermal block.

An HVAC zone is a physical space within the building that has its own thermostat and zonal system for maintaining thermal comfort. HVAC zones are generally identified on the HVAC plans. HVAC zones should not be split between thermal blocks, but a thermal block may include more than one HVAC zone.

A space function is a sub-component of a thermal zone that has specific baseline lighting requirements and for which there are associated defaults for outside air ventilation, occupancy, receptacle loads, and hot water consumption. An HVAC zone may contain more than one space function. Appendix B has a list of the space functions for which defaults and baseline building data are provided. .

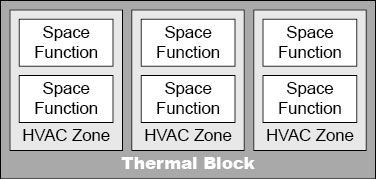

Figure 2.2.1-1 shows the hierarchy of space functions, HVAC zones and thermal blocks.

Figure 2.2.1-1: "Hierarchy of Space Functions, HVAC Zones and Thermal Blocks"

2.2.2 General Guidance

This section provides some general rules and guidance on how to effectively define thermal blocks. Albert Einstein once said “everything should be made as simple as possible, but no simpler” and that is the challenge when creating thermal blocks.1 The energy simulation model should include as few thermal blocks as possible, but as many as are needed. Breaking a building into thermal blocks is a step of the energy modeling process that requires considerable judgment.

Because of differences in the capabilities and limitations of various simulation tools and the extreme variety in size and complexity of buildings to which the rating method may be applied, a rigid set of rules for defining thermal blocks is not possible. Some exercise of user judgment will be required in most cases to determine the most appropriate way to subdivide and model a building.

Defining appropriate thermal blocks will save time for the user and will help to ensure accurate results. However, regardless of how the user chooses to subdivide the rated building, for most purposes, identical subdivisions will be used in modeling the baseline building. It is difficult to predict what impact a faulty decision would have on energy performance, but there is little doubt that the impact on proposed design energy use could be significant.

2.2.3 Number of Thermal Blocks

In general, the smaller the number of thermal blocks that are defined, the lower the user's effort will be to create the building description. However, if too few thermal blocks are defined, simulation results are likely to be less accurate. In order to simplify ratings, users should define as few thermal blocks as possible, consistent with the other guidance in this section. Normally, the number of thermal blocks in a building should not exceed the number of HVAC zones in the building.

2.2.4 Space Use Classification Considerations

Thermal blocks may contain up to ten different space use classifications, provided the spaces have similar space conditioning requirements. If the building area method is used, each thermal block must be assigned to one and only one building area category. For space-by-space classifications that are combined in a single thermal block, the spaces must meet all of the following conditions:

- Use the same operating schedule.

- Use the same space temperature schedule.

- Have similar internal load power densities. Combined lighting, receptacle, and process equipment power densities that differ by no more than 2.0 W/ft² or a factor of two may be considered similar.

- Have similar occupant densities. Occupant densities (i.e., densities represented in floor area per occupant [under peak design conditions]) that differ by no more than a factor of three may be considered similar.

2.2.5 Envelope Load Considerations

Thermal blocks shall consist of spaces having similar envelope loads; for example, thermal loads from solar heat gains and conductive heat losses from roofs. In general, spaces close to the perimeter of the building should be in separate thermal blocks from interior spaces. The following guidance shall be applied in combining HVAC zones into thermal blocks:

- Exterior and interior spaces shall not be combined in the same thermal block, except that exterior spaces without fenestration or doors may be combined with interior spaces in the same thermal block.

- Exterior spaces having different glazed orientations shall not be combined in the same thermal block, except as permitted below.

- Exterior spaces having different glazed orientations but small effective apertures for solar heat gain (i.e., solar heat gain coefficient times fenestration area divided by zone floor area less than 10%) may be combined in a single thermal block.

- Exterior spaces having different glazed orientations but whose orientations differ by 45º or less may be combined in a single thermal block. This is not intended to prevent or discourage modeling of actual or anticipated corner zones or other actual HVAC zones which include fenestration of varying orientations in a single contiguous space.

- Spaces with envelope loads from floors and/or roofs shall only be combined within a single thermal block with spaces having similar loads from floors and/or roofs.

- Separate thermal blocks shall be created when fenestration area varies greatly. For example, a long perimeter corridor with small windows at one end, but all glass at the other should be split into two thermal blocks.

2.2.6 Conformance with HVAC Zones

Thermal blocks shall conform with the actual HVAC zoning as documented on the construction documents or the as-built drawings. "Conform with" as used here means that thermal blocks shall accurately reflect the actual floor areas of the HVAC zones (i.e., to within 5% of actual square footage), and thermal blocks and HVAC zones should share the same bounding surfaces.

2.2.7 Combining HVAC Zones

Under specific conditions, different HVAC zones may be combined into a single thermal block to reduce user input and to simplify the computer description of the building. Zone multipliers may also be used to achieve similar simplification, when this is a feature of the software. Provided all of the following conditions are met, different HVAC zones may be combined to create a single thermal block (or identical thermal blocks to which multipliers are applied):

- No more than ten different HVAC zones are included in any one thermal block.

- All the HVAC zones have similar space conditioning requirements.

- All of the zones are served by the same HVAC system or by the same kind of HVAC system. Perimeter baseboards, unit heaters or fan powered boxes (vs. straight VAV boxes) should not be considered the “same kind” of HVAC system as zones without these features.

- All zones have similar minimum airflows (cfm/ft²) and if any have separate exhaust, this is met generally by transfer air from the other HVAC zones in the thermal block.

2.2.8 Thermal Blocks in Multifamily Residential Buildings

Multifamily residential buildings, including hotel and motel occupancies, should be modeled using one thermal block per unit. Where units are thermally similar, dwelling units or hotel rooms may be combined. Corner units and units with roof or floor loads shall only be combined with units sharing these features.

2.2.9 Plenums

Plenums are spaces above the ceiling and/or below the floor above where lighting fixtures, pipes, ducts and other building services are often located. Plenums may or may not be used as return air plenums. Because of the leakage through the ceiling (typically suspended with lay-in panels), the temperature of the plenum tracks the temperature of the space, except that it is generally warmer because of heat stratification and heat produced by lighting fixtures located at the ceiling or in the plenum.

It is generally recommended that plenums be modeled as separate thermal blocks, but at the modeler’s discretion, they may be combined with conditioned space below for modeling simplicity.

- 1"On the Method of Theoretical Physics" The Herbert Spencer Lecture, delivered at Oxford (10 June 1933); also published in Philosophy of Science, Vol. 1, No. 2 (April 1934), pp. 163-169.

2.2.1 General

This document lists the building descriptors that are used in the simulation. Users must provide valid data for all descriptors that do not have defaults specified and that apply to parts of the building that must be modeled.

2.2.2 Definition of Building Descriptors

Building descriptors provide information about the proposed design and the baseline building. In this chapter, the building descriptors are discussed in the generic terms of engineering drawings and specifications. By using generic building descriptors, this manual avoids bias toward any particular energy simulation engine. The building descriptors in this chapter are compatible with commonly used simulation software.

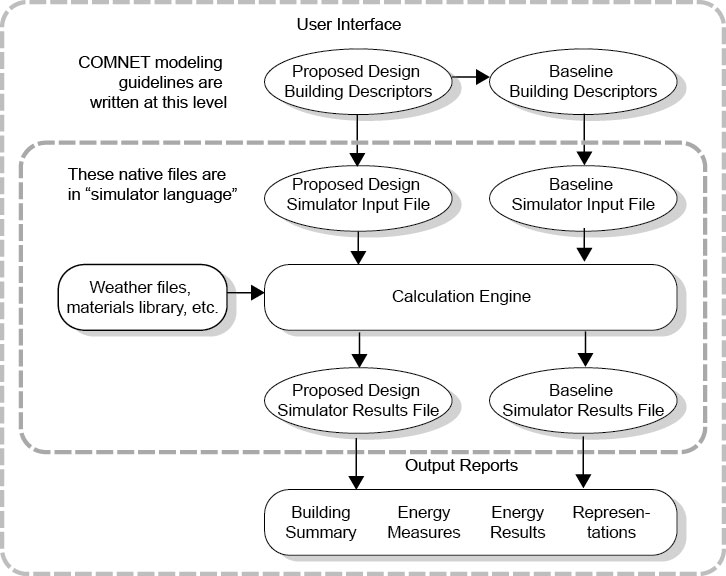

Each energy simulation program has its own way of accepting building information. EnergyPlus, for instance, uses a comma delimited data file called an IDF file. DOE-2 uses BDL (building design language) to accept information. It is the software’s responsibility to translate the generic terms used in this chapter into the “native language” of the simulation program. Figure 1 illustrates the flow of information.

Figure 1. Information Flow

2.2.3 Treatment of Descriptors Not Fully Addressed by this Document

The goal of this document is to provide input and rating rules covering a full range of energy-related features encountered in commercial buildings. However, this goal is unlikely to ever be achieved due to the many features that must be covered and the continuous evolution of building materials and technologies. The baseline building design shall be developed by modifying the proposed design as described in this manual and Standard 90.1 Appendix G, Section G3.1. All building systems and equipment shall be modeled identically in the proposed design and baseline building design, except when specifically noted in this manual. Where the baseline building systems and equipment are permitted to be different from the proposed design the baseline building shall be modeled to meet the mandatory and prescriptive requirements of Standard 90.1, Sections 5 through 10. If there are no mandatory or prescriptive requirements for a system or component in Standard 90.1, then those components shall be modeled as described in this document or it shall follow the requirements of other efficiency or equipment codes or standards applicable to the design of the building systems and equipment.

When the simulation program does not explicitly model a design, material, or device of the proposed design, an exceptional calculation method shall be used if approved by the rating authority.

2.2.4 Energy Components

ASHRAE Standard 90.1 has requirements to address the energy used for building systems and components including energy used for heating, cooling, ventilation, interior and exterior lighting, service water heating, motors, transformers, vertical transportation, refrigeration equipment, computer room cooling equipment and other building systems, components and processes with requirements prescribed in Standard 90.1 Sections 5 through 10.

Both the proposed and baseline building performance ratings must include all components of energy use, including receptacle loads, vertical transportation, garage ventilation, outdoor lighting, and process loads, such as refrigerated cabinets in supermarkets and cleanrooms in laboratories. Minimum efficiency requirements for many of these items are present in the prescriptive and mandatory sections of Standard 90.1 and should be modeled according to Standard 90.1-2019 Sections G1.2 and G1.3.

When allowed by the rating authority or building official, energy end-uses considered noninteractive, meaning they have no significant interactions with the heating and cooling energy components, such as exterior lighting or garage ventilation, can be determined through a side calculation instead of being modeled through the simulation program.

2.2.5 Regulated and Unregulated Energy Use

Regulated energy is the energy used for components of the building with requirements in Standard 90.1 Sections 5 through 10. This includes the energy used for HVAC, lighting, service water heating, motors, transformers, vertical transportation, refrigeration equipment, computer-room cooling equipment, and other building systems, components, and processes with requirements prescribed in Standard 90.1 Sections 5 through 10.

Unregulated energy is the energy used for all other end-uses in the building, which are primarily process loads. Some process loads do have requirements specifically identified in the standard and those are regulated, For example: some refrigeration systems, computer room cooling systems, fume hoods, items plugged into convenience outlets such as personal computers, printers, refrigerators etc. There is a multitude of unregulated energy use within the building that is not addressed by the standard, including but not limited to:

- All the things that are plugged into convenience outlets such as personal computers, printers, coffee machines, and refrigerators; i.e. the receptacle is regulated but the downstream component of the receptacle is not regulated.

- Compressed air systems in manufacturing and warehouse facilities;

- Specialized equipment in laboratories, hospitals, and manufacturing plants.

- Cooking equipment including griddles, fryers, ovens etc.

- Process loads without requirements specifically identified in the standard. For example: computer equipment in the data center, manufacturing equipment, industrial equipment.

- If chiller/boiler is used to provide chilled water or hot water to meet process loads and are covered by conditions in Standard 90.1-2019 Table 6.8.1-3 and Table 6.8.1-6, then the baseline equipment used to model the chilled water and hot water should use the efficiency specified in Standard 90.1-2019 Table G3.5-3 and Table G3.5-6, else it should be modeled as same as proposed.

- Energy used to recharge or refuel vehicles that are used for on-building site transportation purposes are considered unregulated energy and shall be modeled to be the same in the baseline and proposed building model.

- Energy used to recharge or refuel vehicles that are used for off-building site transportation purposes shall not be modeled in the baseline building or the proposed building model.

Energy modelers must be able to distinguish between regulated and unregulated energy use since this is an important factor in determining the PCI target for compliance with 90.1-2019. The target performance cost index (PCIt) assumes that the unregulated energy use is neutral for both the proposed design and the baseline building, and the procedure for determining PCIt has adjustments for the percent of unregulated energy.